Indoor air quality has now become a vital issue for companies since this is linked with the productivity of employees, satisfaction among customers, and well-being. The Indoor Air Quality Management System (AQMS) refers to the comprehensive solution designed for any organization, or firm, in order to monitor, evaluate, and optimize the indoor air quality within its premises. Through this system, businesses can acquire a healthier environment with utmost comfort for its employees and visitors.

Mostly, indoor air quality contains hidden pollutants that many businesses forget about such as dust, mold, volatile organic compounds, and more, which end up irritating the body and causing health problems with discomforts to the employees. An Indoor Air Quality Management System, or AQMS, is a service that helps companies keep these pollutants under control thereby creating a cleaner workspace with an overall improved work experience. It can prevent absenteeism, increase productivity, and actually promote a healthier atmosphere.

Poor indoor air quality can lead to severe health hazards. Workers may suffer frequent headaches, respiratory problems, or long-term exposure effects such as chronic respiratory diseases. The continuous monitoring of AQMS ensures air quality and detects harmful levels of pollutants and allergens; thus, businesses can immediately address these concerns. It thereby provides real-time data to maintain purity in the air and reduces health hazards and protects the workforce.

Duct-mounted ozone generator is one of the integral parts of an Indoor Air Quality Management System (AQMS). This technology neutralizes organic odors, removes dust particles, and controls microbial growth - making indoor air clean and free from harm. In addition, ozone generators function in accordance with OSHA guidelines and, as such, ensures all health and safety regulations are maintained. This feature installation enables the organization to enhance indoor air quality without compromising on energy efficiency.

There are many benefits that will accrue to a business via installing an Indoor Air Quality Management System (AQMS).

Long-term investments in AQMS lead to a healthier and more sustainable environment at work.

Maintaining the optimum air quality is not just something you call a bettermine to ensure comfort, it is a necessity in today's business world. Therefore, companies can implement Indoor Air Quality Management System (AQMS) as a layer of employees’ health protection to ensure cleaner and safer air for employees and customers. Optimizing air quality allows for increased productivity, health, and safety compliance in meeting standards on air safety. It is a good investment for any indoor space.

Today’s Offices, Hotels and other buildings are generally centrally air conditioned and create its own form of indoor air pollution or commonly known as “sick building syndrome” due to nearly-air tight construction and absence of enough fresh air from outside.

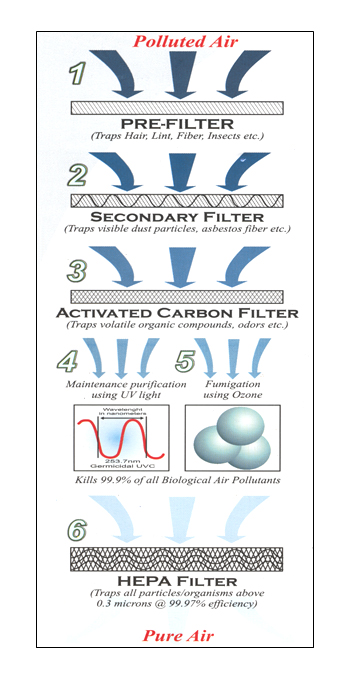

Ozone is a very strong oxidizer and has powerful purifying property. Ozone is capable of oxidizing various organic odours and destroys viruses and bacteria present in the air, that are not only offensive but harmful as well. It has a strong potential to remove organic odour by oxidizing odour-causing molecules. Ozone converts / removes smoke (suspended carbon particles in air) to Carbon die-Oxide.

A very small and safe concentration of Ozone can purify and de-odorize air much better than any de-odorizing spray. Today Ozone is considered by most to be the best available and advanced technology and a much better alternative than using chemicals.

Ozone Air purification is a continuous and safe process. There are two type of Ozone air purifier presently available, these are:

Duct mounted Ozone Generators : In this system Ozone cells are mounted inside the air duct and small amount of air passes through the Ozone unit. Out going Ozone rich gas from the Ozone unit is mixed with total air stream and does the purification job.

Ozone Injection into Air Duct : In this system Ozone is produced outside the duct and injected into the duct at a suitable location. In this system generation of Ozone, Control of concentration and quantity is independent of airflow, air quality, presence of moisture and any kind of contaminations or suspended impurities.

This system configuration can provide a much better control of Ozone mixing into air duct. Further this is a much more stable, reliable, maintenance friendly and does not need frequent cleaning and maintenance on the system. To conclude it is little more expensive and a long lasting system.

Ozone required to be dosed in a specific area e.g. a hotel room, restaurant, bar or a basement office depends upon the size (volume) of the room, position of air handling system, level & nature of Odour, temperature of the area, presence of moisture and dust.

Ozone quantity is correctly estimated by taking various parameters into consideration using a computer programme. However for a rough estimation, as a thumb rule, for an area of less odour and clean e.g. hotel rooms, offices, conference rooms, 1 gm/hr Ozone is required for 6,000 Cu.ft. space, while for area of higher bacterial contamination and foul smell as butchery, basement rooms, moist stinking areas, 1 gm/hr Ozone is need for 3,000 Cu.ft. space.

A very small Ozone concentration of 0.02 to 0.08 PPM is adequate for achieving air purification & deodorization, however on this concentration little more time is needed to get the desired results. Actual concentration required to be maintained at a place depends upon the presence of persons, type and nature of odour, the criticality of the area, duration required to purify and extent of foul smell. If no body is present in the room higher concentrations can be used for faster results.

Ozone Concentration should not exceed more than 0.1 PPM where persons are present, for eight hours or more per work day, and no person be exposed to a ceiling concentration of Ozone in excess of 0.6 mg/m³ (0.3 PPM by volume) for more than ten minutes. This limit is set as per OSHA standards.

Concentration of Ozone in air is monitored & controlled by Ozone Monitoring system manufactured by CREATIVE OZ-AIR (I) PVT. LTD.”. For Automatic regulation a feed back loop is used. The monitoring system is equipped with high & low level relay outputs, which are used for controlling Ozone concentration at the required level.