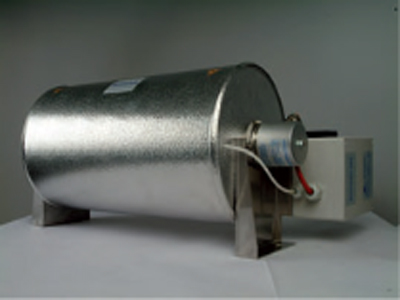

The Ozone Destructor by Creative OZ AIR is a tremendous solution for industries that use ozone technology. By using it, excess ozone is removed from the environment in a safe and efficient way, and ozone levels will be safe- an adequate amount to avoid all potential health hazards as well as unnecessary damage to equipment. Above all, your industry has to be regulated by the set industry standards.

The Ozone Destroyer has been primarily configured to break down and decompose extra ozone into oxygen, thereby preventing ozone from reaching toxic levels within an industrial environment. In this manner, it avoids the accumulation of harmful concentrations of ozone, thus protecting both personnel and equipment from exposure.

Organizations in the field of water treatment, food processing, and manufacturing require strict regulation on the level of exposure to ozone. This is because the Ozone Destroyer allows the respective industries to adhere to such safety provisions since it ensures that the ozone levels do not exceed permissible limits. This eliminates fines and maintains a safe working condition.

By safely removing excess ozone, the Ozone Destructor ensures that businesses keep their ozone systems efficient through continuous operation without any worry of shutdown and damage to sensitive equipment.

Ozone is used in treatment plants to disinfect and purify treated water. The use of an Ozone Destructor will ensure that all the remaining ozone is destroyed after treatment, thus avoiding any exposure to the workers.

In food production sites where ozone is used for sterilization and conservation, the Ozone Destructors prevent accumulation of the gas in the air; therefore, food safety and health standards are met.

Industrial production sites utilizing ozone as an additive in air and water purification employ the Ozone Destructors. These eliminate harmful extra ozone that can be subsequently utilized, while ensuring safe working conditions and preventing excess levels of harmful components in air from spiraling out of control.

Creative OZ AIR's Ozone Destructor is an essential element for companies using ozone. It removes extra ozone in the safest, most efficient, and cost-effective manner possible while ensuring safety at every level of a facility through employees and equipment. For industries looking to keep their ozone levels below the dangerous limit, the Ozone Destructor is a solid investment a business should make.

An ozone destructor is a device or system designed to break down ozone molecules (O3) into oxygen (O2) or other harmless substances.

Ozone can be harmful to human health and the environment in high concentrations. Ground-level ozone can cause respiratory problems, eye irritation, and damage to plants and materials.

Ozone destructors are used in various applications where ozone is produced as a byproduct or is present in undesired concentrations. This includes industrial processes, air purification systems, and wastewater treatment plants.

Ozone destructors employ different methods to break down ozone molecules, including thermal destruction (high temperatures), catalytic destruction (using catalysts), chemical destruction (using chemical agents), and UV photolysis (using ultraviolet light).

Ozone destructors help mitigate the harmful effects of ozone by converting it into oxygen or other harmless substances, thereby reducing health risks and environmental damage.

Some ozone destruction methods, such as catalytic destruction and UV photolysis, are more energy-efficient than others, such as thermal destruction. The choice of method depends on factors such as efficiency requirements and energy considerations.

Ozone destructors themselves are generally safe to use when operated correctly. However, proper safety precautions should be followed, especially when dealing with high temperatures, chemical agents, or UV light.

Factors to consider include the concentration of ozone, required efficiency, energy considerations, specific application requirements, and regulatory compliance.

Yes, like any other mechanical or chemical system, ozone destructors may require maintenance to ensure optimal performance and longevity. This may include regular cleaning, replacement of consumable parts, and periodic inspections.

Depending on the application and location, there may be regulations or guidelines governing the use of ozone destructors to ensure environmental protection and public safety. It's important to comply with relevant regulations and standards.