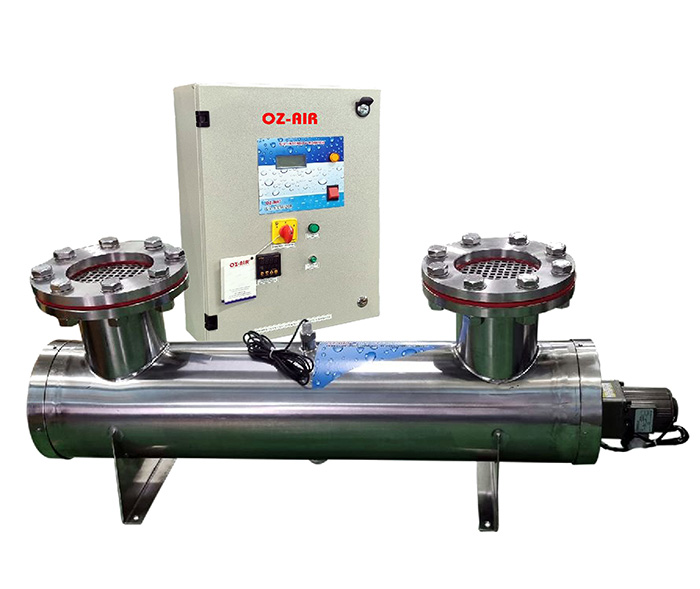

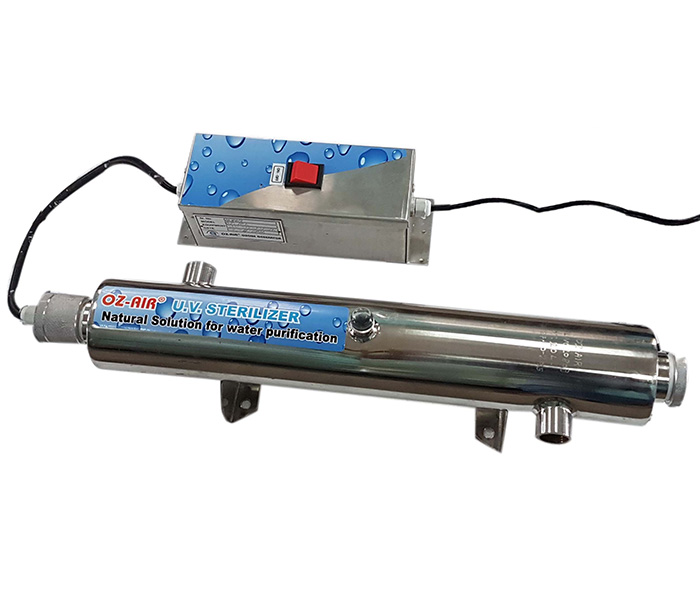

The UV Sterilizers from Creative OZ AIR are one of the most modern chemical-free solutions in today's competitive industrial and commercial environment for the sterilization of air, water, and surfaces. They eliminate harmful microorganisms such as bacteria, viruses, and mold using ultraviolet (UV-C) light. Businesses need these disinfested UV sterilizers to attain the ultimate hygiene and safety levels, especially in the healthcare, food processing, and manufacturing industries.

The UV Sterilizers utilize UV-C light, which penetrates into the cells of pathogenic microorganisms and disqualifies them of their ability to breed, thus nullifying their multiplication. It is a strongly effective means of disinfecting air, water, and surfaces, keeping your facility at its optimal hygiene levels.

In contrast to chemical-based disinfection, which typically relies on traditional methods, UV Sterilizers provide a clean element that is environmentally friendly in most cases. The element leaves no trace of chemicals used, thus protecting employees against toxins that may be harmful to them in the long run.

Business entities that deal in the productions of goods, health care, and food industries require serious implementation of hygienic and safety measures. The UV Sterilizers ensure full compliance to these expectations through steady and reliable sterility and minimize contamination possibilities while keeping a business within regulatory constraints.

The UV Sterilizers are designed to be very long lasting with minimal maintenance. This is, therefore, making the measure an energy-efficient one that helps companies reduce their running costs. It is for such reasons that the equipment remains a very cost-effective investment for any business in need of ensuring reliable disinfection without such heavy running costs.

UV-C Technology: Neutralizes harmful microbes with no chemicals involved and without harming the environment.

Durable Design: Designed for continuous operation in industrial conditions, the UV Sterilizers are extremely long-lasting and require minimal maintenance to last longer.

Eco-Friendly Operation: Chemicals are not used in disinfection, so the environment is not harmed in any way through residues.

Easy Installation and Usage: Easy integration with existing systems to make them useful seamlessly. The sterilizers are designed to provide automatic operation and complete comfort.

UV Sterilizers disinfect patient rooms, operating theaters, and medical equipment in healthcare settings. In that regard, it reduces the risk of healthcare-related infection and increases safety for patients and doctors.

Maintaining the sterile processing areas in the food industry is crucial in order to avoid contamination. When disinfecting surfaces and equipment or even harmful pathogens present in the air, UV Sterilizers are used to permit businesses to function according to the food safety standards.

UV sterilizers benefit manufacturing facilities by providing a clean environment, especially the ones processing consumers' goods or pharmaceuticals. They can help ensure that quality standards are met and the products are safe for consumption.

Sterilizers that utilize UV can be installed into the HVAC systems of large commercial and industrial spaces to provide for air sterilization. In turn, it further enhances air quality by removing airborne pathogens, lessens the impacts of sicknesses, and creates healthier indoors.

The UV Sterilizers by Creative OZ AIR offer a forceful, chemical-free disinfection solution to businesses seeking hygiene and disinfection at the highest levels. These sterilizers have efficient, safe, and eco-friendly operation features suitable for industries dealing with health care, food processing, or manufacturing. These sterilizers can be an important investment for businesses looking for an efficient and cost-effective approach to enhancing sanitation and meeting the regulations of the specific industries concerned.

UV sterilizers work by emitting ultraviolet light, typically in the UVC spectrum (around 254 nanometers). This UV light disrupts the DNA and RNA of microorganisms, such as bacteria and viruses, rendering them unable to replicate and effectively killing them.

UV sterilizers are effective against a wide range of microorganisms including bacteria, viruses, algae, molds, and protozoa. However, the effectiveness may vary depending on factors such as UV dose, contact time, and the type of microorganism.

UV sterilizers offer several advantages, including: Chemical-free disinfection: UV sterilization does not require the use of chemicals, making it environmentally friendly and safe for use in various applications.

Effective against a wide range of microorganisms: UV light can kill or inactivate bacteria, viruses, algae, molds, and other pathogens.

No residual byproducts: Unlike chemical disinfection methods, UV sterilization leaves no residual byproducts in the water or air. Low maintenance: UV sterilizers require minimal maintenance compared to other disinfection methods, with periodic lamp replacement being the primary requirement.

UV sterilizers are used in various applications including: Water purification: In aquariums, water treatment plants, residential water systems, and wastewater treatment facilities.

Air purification: In HVAC systems, air purifiers, and germicidal lamps to sterilize the air.

Surface disinfection: In hospitals, laboratories, food processing facilities, and other settings to sanitize surfaces.

UV sterilizers are generally safe when used properly. However, direct exposure to UV light can be harmful to the skin and eyes, so it's important to follow safety precautions and use protective equipment when handling UV sterilizers.

Proper maintenance of UV sterilizers is essential to ensure optimal performance. This typically includes: Regular cleaning of the quartz sleeve or protective covering to remove any buildup that may reduce UV transmission. Periodic replacement of UV lamps according to the manufacturer's recommendations. Checking and replacing any worn or damaged components as needed.

Several factors can affect the effectiveness of UV sterilizers, including: UV dose: The intensity and duration of UV exposure required to kill microorganisms. Water quality: Turbidity, pH, and the presence of substances such as organic matter can affect UV transmission and effectiveness. Flow rate: The rate at which water or air passes through the UV sterilizer can impact the contact time and effectiveness of disinfection.