Creative Oz Air offers PSA Nitrogen Generator that produce high-purity nitrogen gas directly at your site. Whenever you want, wherever you want. By using advanced PSA Technology (Pressure Swing Adsorption), these generators deliver nitrogen with purity levels from 99% to 99.99995%. PSA Nitrogen Generator ensures the production processes of industries remain uninterrupted and efficient. By generating your own nitrogen with a PSA Nitrogen Generator, you save costs, avoid bulky cylinder dependency, avoid waiting time for nitrogen deliveries, and maintain a reliable gas supply for your plant.

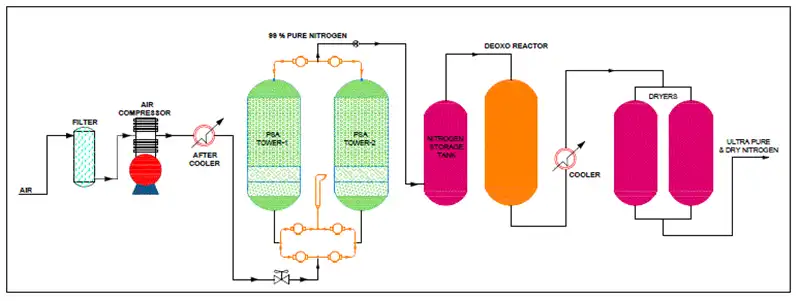

A PSA Nitrogen Generator is a machine that works on PSA technology to separate nitrogen from the mixture of air. PSA stands for Pressure Swing Adsorption. Basically, this machine uses two towers and Carbon Molecular Sieves (CMC) to separate Nitrogen (N2) and Oxygen (O2) from the air. CMS traps unwanted gases and separates them, and only allows Nitrogen and Oxygen to pass through. When one tower gets saturated, the next tower starts working to make sure that there is no delay in the gas supply. Nitrogen Generator is a compact and skid-mounted system, fixed together on a base. This system works with electricity to generate nitrogen.

There are two types of PSA Generators: PSA Nitrogen Generator, which provides a constant supply of nitrogen, and the other is PSA Oxygen Generator, in charge of uninterrupted Oxygen supply.

The PSA nitrogen generator is a combination of its components. The nitrogen generator works in two parts:

This system has an Air Compressor that suck air around us and compresses it to high pressure. Then, an Air Dryer removes moisture from the compressed air. To save CMS from the dust, oil, and other contaminants in the compressed air, Pre-Filters and Fine Filters are used. They filter air and reduce CMS damage. In the last, the Air Receiver Tank stores compressed air.

This is the main unit of the nitrogen generator. This is where nitrogen is separated from the air:

PSA Nitrogen Generators are used in a wide range of industries, including:

Work: Packaging, Preservation, and Inerting

Packaging: While the packaging of food items, like packets of chips and

other food

items, or a coffee can, is filled with nitrogen. Nitrogen removes the oxygen

inside

the packets and can. Oxygen, a highly reactive gas and starts oxidizing the

food.

Nitrogen keeps the products fresh for a long time.

Preservation: Nitrogen is also used for storing oil, juice, wine, and

other

beverages. Nitrogen ensures that they don't come into contact with oxygen, so

their

taste and color remain the same.

Work: Production and storage of medicines

Sensitivity, Oxidation, and Protective Atmosphere: Medicines are very sensitive products, and there is no compromise for their purity and safety. Medicines are highly sensitive to oxygen and moisture, which could lead to a chemical reaction. Because of oxidation, medicine can lose its effectiveness, and its chemical structure also. Nitrogen is a stable(inert) gas and is used as a protective shield in tanks and mixing vessels. As a result, it keeps oxygen out, which ensures that medicinal drugs maintain their purity and shelf life.

Work: Protection from Oxidation and Moisture With Inert Atmosphere

Nitrogen for protective atmospheres: The use of nitrogen is a fundamental necessity in the electronics and semiconductor industry. Semiconductor chips and circuit boards are very small and sensitive. Even a small amount of oxygen or moisture during manufacturing can damage the chip. Nitrogen creates a dry and oxygen-free environment. Components are kept in a nitrogen atmosphere during production, so they don't lose their quality and avoid damage.

Work: Safety and Quality Control

Blanketing and Inerting: The use of nitrogen gas in the chemical and petrochemical industry is a mandatory and standard procedure for safety and quality control. Petrol, diesel, and many industrial chemicals vaporize easily. Oxygen helps ignite fire and can cause an explosion. In blanketing, an inert layer of nitrogen is created just above the surface of the liquid in the storage tank. This layer acts like a "blanket" that completely cuts off oxygen from the vapors. The absence of oxygen reduces the risk of fire or explosion.

Work: Safety and quality control

Prevent Oxidation: The use of PSA nitrogen generators is an established and mandatory safety standard in metallurgical, oil and gas, and related heavy industries. Heavy metal industries work at high temperatures. Oxygen can react with melted metal and cause scale or rust on the surface. Nitrogen creates an oxygen-free environment for metal work. That keeps metal bright, rust-free, and of high quality. The same goes for the oil and gas industry, where nitrogen helps prevent oxidation.

In short, whenever you have to prevent oxygen-induced problems or damage like corrosion, fire, spoilage, or oxidation, a Nitrogen Generator is used. Nitrogen's inerting(non-reacting or inactive) nature makes it the best choice for these industries.

For PSA Nitrogen Generators, there are various types of well-known companies and brands. But Creative OZ Air offers special benefits. Creative Oz Air also known as PSA Nitrogen Generator Manufacturer. As a leading Ozone Generator Manufacturer, it's our priority to get customer satisfaction. When you use Creative Oz Air’s PSA Nitrogen Generators, you get to experience various advantages, including:

There are plenty of perks for choosing a Nitrogen PSA Generator over Nitrogen Cylinders or liquid nitrogen. A Nitrogen PSA Generator provides an uninterrupted supply of nitrogen on-site without any extra cost. Transportation and handling of nitrogen deliveries are quite high. PSA nitrogen generator eliminates these problems.

| Criteria | PSA Nitrogen Generator | Nitrogen Cylinder |

|---|---|---|

| Cost | Running cost is low. | Costs of rental/delivery would increase over time. |

| Transfer and handling | It is not required. | Extremely cumbersome process. |

| Purity | High purity nitrogen is produced steadily. | Purity levels are not uniform, and can vary from cylinder to cylinder. |

| Efficiency | Unlimited gas supply that is continuous. | Interruption in supply of cylinder is possible. |

| Dependence | No dependency since you produce nitrogen yourself. | You have to depend on suppliers to supply cylinders. |

| Convenience | Maintenance easy and low. | Frequent cylinder replacement needed. |

The principle of selective adsorption governs the working of the PSA nitrogen generator. Compressed air passes through a vessel that has carbon molecular sieve (the adsorbent material). The sieve adsorbs oxygen and lets nitrogen go through. Adsorbed oxygen is then released, so you can get pure nitrogen as the end product of the process.

The PSA Nitrogen generator we offer can offer purity up to 99.9999%. Depending on your needs, we can offer you a generator that can produce the best purity level to meet your application requirements.

You can keep these factors in mind while choosing this particular machine:

Look for a generator that meets all your needs, and is offered by a reputed manufacturer.

You must carry out routine maintenance like changing the filter and replenishing the adsorbent material. The schedule for maintenance depends on your use and the environmental condition in your premises.

Yes, it is possible. Retrofitting can be used to integrate our PSA Nitrogen air generator into your existing compressed air systems. Proper planning is required. The right setup and configuration will help in making this possible.