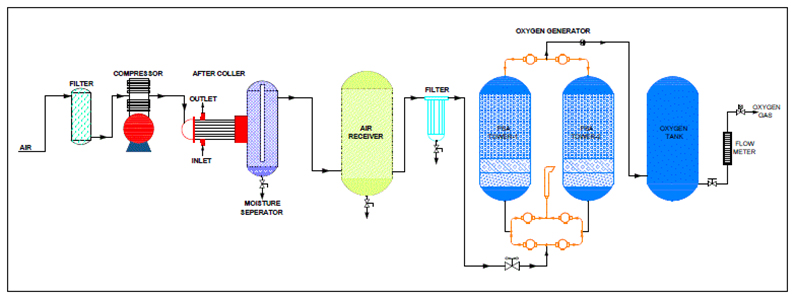

Separation of Oxygen from air is effected by PSA (Pressure Swing Adsorption) process where adsorption of Nitrogen is carried out by using synthetic zeolite, known as molecular sieves. Oxygen generator, consists of two adsorption vessels, filled with molecular sieves. These vessels are alternately charged with compressed air where, Nitrogen and other impurities are adsorbed and oxygen flows into an oxygen surge tank. After the adsorption cycle, one vessel is depressurized to atmospheric pressure, thereby discharging the adsorbed nitrogen and sieve bed is regenerated by counter current oxygen flow from the buffer tank.

Oxygen generator are tailor made equipment and are manufactured as per customer’s requirements. However, standard units are available in the capacity of 1, 2, 5, 10, 25, 50, 75, 100, 150, 200 Nm3/hr. the gas generators can be manufactured in any desired capacity.

| Items | PSA Oxygen Generator | PSA Oxygen Generator |

|---|---|---|

| Cost | Low Running Costs | Increasing delivery and rental costs over time |

| Transfer & Handling | Not Required | Cumbersome |

| Purity | Uniform and steady high Nitrogen purity | Varying Purity Levels from a cylinder to another |

| Efficiency | Continuous and Unlimited Gas Supply | Gas supply interruptions at inconvenient times |

| Dependency | Dependency on Suppliers | No Dependency |

| Comfort | Low maintenance | Frequent Replacements |

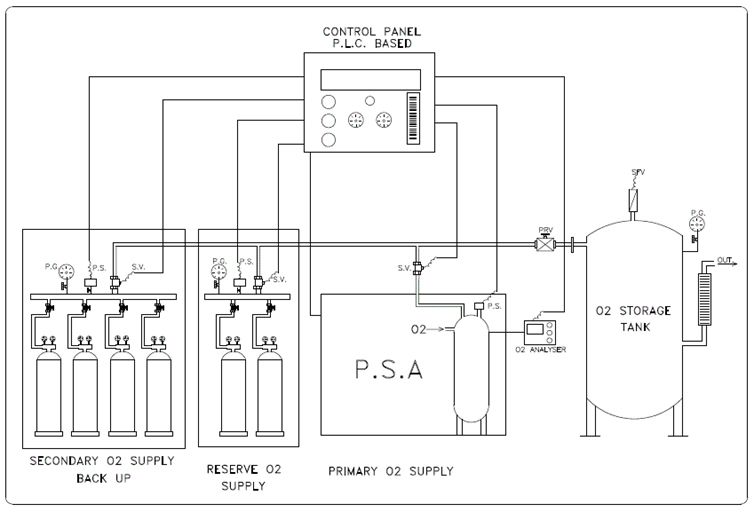

Our Oxygen generators are most suitable for medical application in providing uninterrupted supply of oxygen round the clock. As per US pharmacopeia 93% ± 2% purity oxygen is suitable for Medical Applications. Fully automatic Hospital Oxygen systems can be supplied with reserve oxygen supplies.

The Hospital dependency on scarce Oxygen Cylinders can be avoided. Benefits include low cost, decreased administrative work, continuous and reliable Oxygen supply round the clock. Number of such Oxygen Generators are in use, in India, Europe, Japan & America.

A PSA Oxygen Generator is a device used to produce oxygen gas from ambient air through the process of Pressure Swing Adsorption (PSA). It selectively adsorbs nitrogen from compressed air, leaving behind a higher concentration of oxygen.

The generator operates by adsorbing nitrogen molecules from compressed air using a material with a high affinity for nitrogen, such as zeolite or carbon molecular sieve. The nitrogen is then desorbed when the pressure is reduced, leaving behind oxygen-enriched gas.

The main components include adsorption vessels filled with adsorbent material, compressor, pressure swing valves, flow control valves, oxygen storage tanks, and control systems.

PSA Oxygen Generators can typically produce oxygen with purity levels ranging from 93% to 99.9%, depending on the specific requirements of the application.

Advantages include on-site production, cost-effectiveness, continuous operation, high reliability, ease of installation, and the elimination of the need for oxygen cylinders or liquid oxygen deliveries.

They are used in various applications, including medical facilities (hospitals, clinics), water treatment plants, aquaculture, ozone generation, glass blowing, metal cutting, and other industrial processes.

Regular maintenance, including filter replacement, monitoring of pressure and purity levels, and periodic inspections, is essential to ensure optimal performance and longevity of the system.

Yes, manufacturers often offer customization options to tailor the generator's capacity, purity levels, and other specifications to meet the specific needs of the customer's application.

While the operation of a PSA Oxygen Generator is relatively straightforward, operators may benefit from training provided by the manufacturer or distributor to ensure safe and efficient operation.

Yes, they are considered environmentally friendly because they produce oxygen on-site without the need for transportation or storage of oxygen cylinders, reducing carbon emissions associated with transportation. Additionally, they do not consume any chemicals in the oxygen generation process.