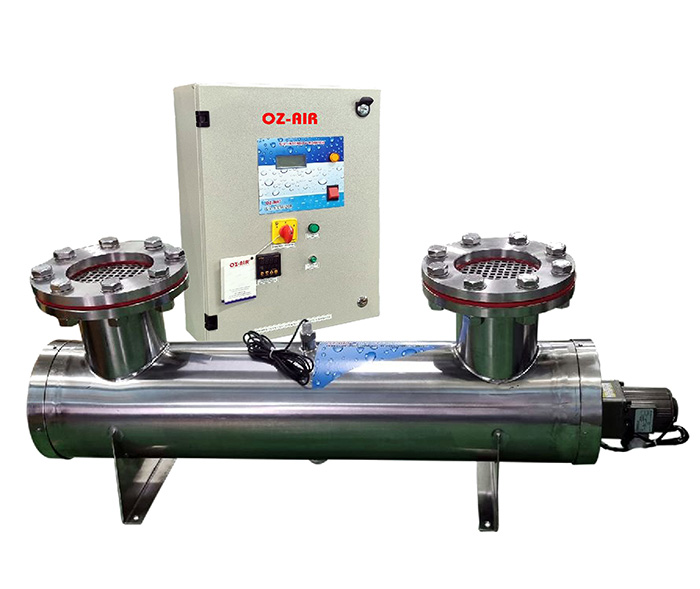

Unlike ordinary UV systems the OZ-AIR OT-L SERIES & OZ-AIR SIGMA SERIES are designed to effectively handle challenges posed by the complexity of tertiary treated wastewater having low UV transmission due to high amounts of BOD, COD and TSS. OZ-AIR UV’s State-o-the-art proprietary Technology allows disinfection at lower capital and operating costs. The germicidal effect of the UV light inactivates most BOD, COD, TOC, Colour, micro-organisms such as bacteria, viruses & parasites.

UV is known to be particularly efficient to inactivate Cryptosporidium Parvum and Giardia Lamblia. High Output Amalgam lamps have an action on nucleic acid and proteins for micro-organisms inactivation. The UV dose (UV intensity x contact time) defines the treatment efficiency whichis provided by the unit. The effective dose applied depends on the UV transmittance of water to be treated as well as the proper hydraulic design of the unit.

The High output Amalgam lamps are powered by High Efficiency Electronic ballasts. The lamps are inserted in pure Synthetic quartz sleeves isolating them from the water. The lamps can be easily changed when indicated by the microprocessor control unit.

UV sensor is installed to monitor UV radiation. An optimal wiper system is available for cleaning the UV lamp quartz sleeves.

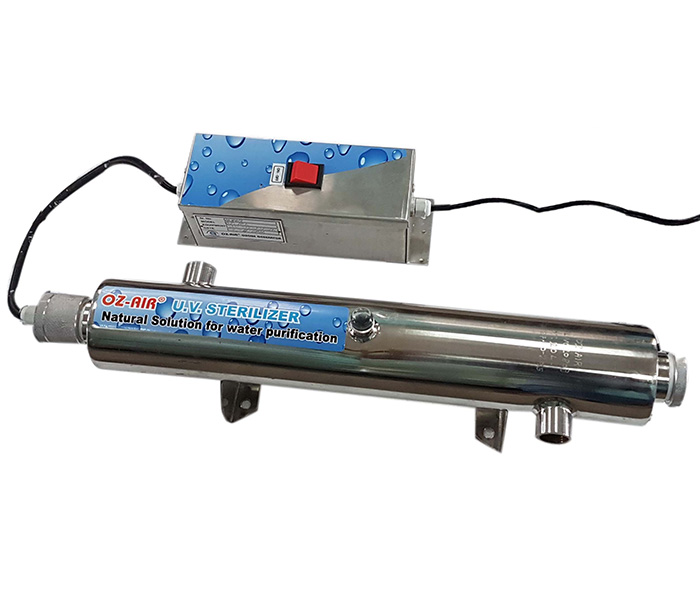

UV sterilizers work by emitting ultraviolet light, typically in the UVC spectrum (around 254 nanometers). This UV light disrupts the DNA and RNA of microorganisms, such as bacteria and viruses, rendering them unable to replicate and effectively killing them.

UV sterilizers are effective against a wide range of microorganisms including bacteria, viruses, algae, molds, and protozoa. However, the effectiveness may vary depending on factors such as UV dose, contact time, and the type of microorganism.

UV sterilizers offer several advantages, including: Chemical-free disinfection: UV sterilization does not require the use of chemicals, making it environmentally friendly and safe for use in various applications.

Effective against a wide range of microorganisms: UV light can kill or inactivate bacteria, viruses, algae, molds, and other pathogens.

No residual byproducts: Unlike chemical disinfection methods, UV sterilization leaves no residual byproducts in the water or air. Low maintenance: UV sterilizers require minimal maintenance compared to other disinfection methods, with periodic lamp replacement being the primary requirement.

UV sterilizers are used in various applications including: Water purification: In aquariums, water treatment plants, residential water systems, and wastewater treatment facilities.

Air purification: In HVAC systems, air purifiers, and germicidal lamps to sterilize the air.

Surface disinfection: In hospitals, laboratories, food processing facilities, and other settings to sanitize surfaces.

UV sterilizers are generally safe when used properly. However, direct exposure to UV light can be harmful to the skin and eyes, so it's important to follow safety precautions and use protective equipment when handling UV sterilizers.

Proper maintenance of UV sterilizers is essential to ensure optimal performance. This typically includes: Regular cleaning of the quartz sleeve or protective covering to remove any buildup that may reduce UV transmission. Periodic replacement of UV lamps according to the manufacturer's recommendations. Checking and replacing any worn or damaged components as needed.

Several factors can affect the effectiveness of UV sterilizers, including: UV dose: The intensity and duration of UV exposure required to kill microorganisms. Water quality: Turbidity, pH, and the presence of substances such as organic matter can affect UV transmission and effectiveness. Flow rate: The rate at which water or air passes through the UV sterilizer can impact the contact time and effectiveness of disinfection.